Processing Plant

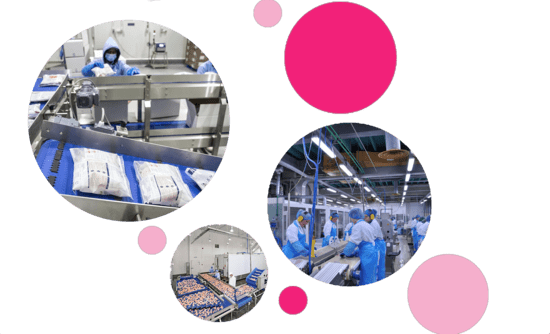

The processing plant is equipped with the latest technology and machinery, which allows for efficient and hygienic processing of the seafood products. The plant has a strict quality control process that ensures that only the highest quality seafood products are packaged and distributed to customers.

12k

SquareMeter

20

Cold StorageRooms

100+

ProfessionalEmployees

Plant

The plant is divided into different sections for processing different types of seafood. Each section is staffed by highly trained personnel who specialize in the processing of that particular type of seafood. This allows for maximum efficiency and ensures that each product is processed to the highest standard.

Processed

Once the seafood is processed, it is immediately frozen or packaged, ensuring that it remains fresh and retains its natural flavor. The packaging is done using high-quality materials that are designed to protect the seafood from contamination and damage during transportation.

Value-added

In addition to processing fresh seafood products, the plant also produces a range of value-added seafood products. These products are made from high-quality seafood and are processed using advanced technology to ensure that they retain their natural flavor and texture.

Sustainability

Jel Seafoods processing plant is committed to sustainability and responsible fishing practices. The plant ensures that all seafood products are sourced from responsible and sustainable fishing practices, which helps to protect the environment and promote ethical fishing practices.

Producing

Overall, the Jel Seafoods processing plant is a crucial component of the company's operations. It enables the company to produce and distribute high-quality seafood products to customers all over Malaysia while ensuring that sustainability and responsible fishing practices are maintained.

Receiving and storage:

This section is where the raw seafood is received from fishermen or suppliers and stored in a refrigerated area until it is ready to be processed.

Packaging:

After processing, the seafood is packaged for sale. This could involve placing it in cans, vacuum-sealed bags, or other containers.

Quality control:

Throughout the processing and packaging process, quality control measures should be in place to ensure the seafood meets safety and quality standards. This could involve inspecting the seafood for defects, monitoring temperature and moisture levels, and testing for contaminants.

Shipping:

Once the seafood has been processed and packaged, it is ready to be shipped to customers or distributors. This section involves loading the seafood onto trucks or other transport vehicles and ensuring it is properly labeled and documented for shipping.

CONSISTENT QUALITY

We use premium products and provide the best services in the industry.

Jels processing facilities are equipped with state-of-the-art equipment and technology that ensure the seafood products are processed safely, hygienically, and efficiently. The processing plant is staffed by highly trained personnel who oversee the entire production process to ensure that the products meet the highest quality standards. The company's commitment to quality and safety has earned it numerous certifications, including HACCP, GMP, and Halal.

Processing Plant has a strong export market and supplies its products to customers in Asia, Europe, and North America. The company's export success is due in large part to its commitment to quality, safety, and sustainability. JEL Seafood Processing Plant's reputation for excellence has made it a preferred supplier of seafood products to many of the world's leading food companies. Overall, JEL Seafood Processing Plant is an exemplary seafood processing.

Sustainable Fisheries One of the unique features of JEL Seafood Processing Plant is its focus on sustainability. The company is committed to promoting sustainable fishing practices and ensuring that its products are sourced from sustainable fisheries. The company works closely with its suppliers to ensure that they adhere to sustainable fishing practices, and it actively supports initiatives that promote sustainable fisheries.

Benifits

Our seafood processing plant in Malaysia has numerous benefits for both the country and its citizens!

Job Opportunities

One major benefit is the creation of job opportunities. Jel seafood processing plant requires a significant amount of labor, from workers in the plant to truck drivers transporting the seafood to various locations. The jobs created help reduce unemployment rates and improve the economy. Additionally, these jobs are providing training and skill-building opportunities for local workers, increasing their long-term employability.

Exports

Another benefit of Jel seafoods processing plant in Malaysia is the potential for increased exports. Malaysia has a rich marine biodiversity and seafood is a major export for the country. By processing seafood locally, Malaysia is potentially increasing its exports and benefit from the added value of processed products. This is helping to diversify the country's exports and increase its competitiveness in the global market.

Environment

Jel seafoods processing plant in Malaysia also has a positive environmental impacts. By processing seafood close to Penang port, the need for transportation of seafood to other cities by truck would be reduced, thereby decreasing the carbon footprint of the industry. Additionally, our local processing plant is helping to ensure that seafood is processed safely and hygienically, reducing the risk of contamination and food-borne illness.

Social

Jel seafood processing plant has also have social benefits. The industry is providing a platform for local fisherman to sell their catch to the processing plant, providing them with a reliable source of income. This is helping to support local fishing communities and help preserve traditional fishing practices. Additionally, the processing plant is providing social services such as health care and education to its workers and their families.

E-MAIL

E-MAIL Whatsapp

Whatsapp Call

Call